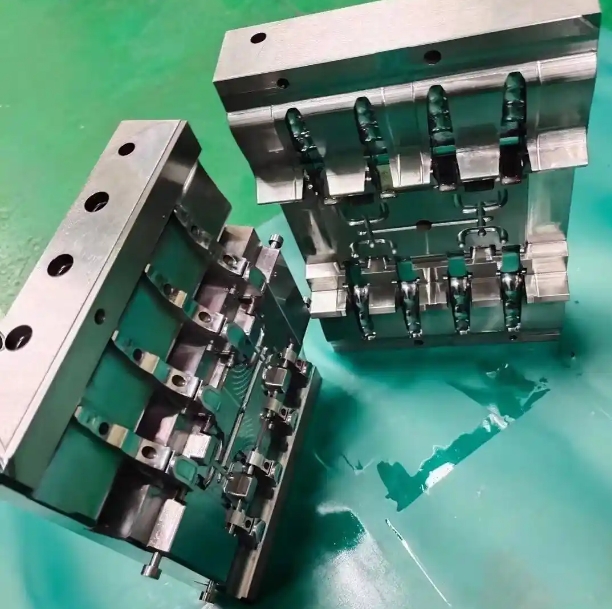

Injection molds are the backbone of plastic manufacturing, shaping products from automotive components to consumer electronics. However, their performance and longevity depend heavily on one critical factor: regular maintenance. A poorly maintained mold can lead to costly downtime, defective parts, and premature failure. This article answers the pressing question, “How often should injection molds be maintained?” while sharing actionable strategies to extend their lifespan—packed .

1. Understanding the Injection Mold Maintenance Cycle

There’s no universal timeline for mold maintenance, as frequency depends on factors like production volume, material type, and operating conditions. However, industry experts recommend the following guidelines:

Daily/Weekly Checks:

Inspect for surface wear, corrosion, or residue buildup.

Clean vents, ejector pins, and cooling channels to prevent blockages.

Scheduled Maintenance (Every 10,000–50,000 Cycles):

Disassemble the mold for deep cleaning and lubrication.

Replace worn components (e.g., springs, bushings, sliders).

Track cycles using IoT-enabled tools for precision

Annual Overhaul:

Conduct thorough inspections of alignment, parting lines, and cooling systems.

Test for dimensional accuracy and polish surfaces if needed.

2. 7 Proven Tips to Extend Injection Mold Lifespan

Maximizing mold longevity isn’t just about maintenance frequency—it’s about adopting smart practices.

Tip 1: Optimize Cooling Systems

Poor cooling causes thermal stress and warping.

Regularly flush channels to remove scale or debris.

Tip 2: Use High-Quality Lubricants

Apply non-greasy, high-temperature lubricants to moving parts.

Avoid over-lubrication, which attracts dust and contaminants.

Tip 3: Monitor Material Compatibility

Abrasive materials (e.g., glass-filled polymers) accelerate wear.

Adjust maintenance schedules for harsh materials.

Tip 4: Polish Surfaces Strategically Over-polishing can alter cavity dimensions.

Tip 5: Address Wear Early

Replace damaged ejector pins or sliders before they cause misalignment.

Tip 6: Control Humidity and Corrosion

Store molds in dry environments with anti-rust coatings.

Silica gel packs or dehumidifiers prevent oxidation.

Tip 7: Leverage Advanced Monitoring Tools

Use sensors to track temperature, pressure, and cycle counts in real time.

Predictive analytics flag issues before failures occur.

3. Common Mistakes That Shorten Mold Lifespan

Avoid these pitfalls to protect your investment:

Ignoring Minor Defects: Small cracks or burrs escalate into major failures.

Skipping Documentation: Track maintenance history to identify patterns.

Using Incorrect Cleaning Agents: Harsh chemicals damage surfaces.

4. The ROI of Proactive Mold Maintenance

Regular upkeep isn’t an expense—it’s a profit-saving strategy:

Reduces downtime by up to 30%.

Cuts scrap rates and material waste.

Extends mold lifespan by 2–3x, delaying costly replacements.

Smart Maintenance = Sustainable Production

There’s no one-size-fits-all answer to “How often should injection molds be maintained?”—it hinges on your production demands and material choices. However, by adhering to a disciplined maintenance schedule, adopting advanced monitoring tools, and addressing wear proactively, manufacturers can dramatically extend mold lifespan, reduce costs, and maintain consistent product quality.