3D printing technology originated in the late 1980s. 3D printing technology has been cited by scientists from various countries and has officially entered people's lives. Injection molding technology is a processing technology that is widely used in traditional industries. It is often used to compare 3D printing technology to distinguish which is more important. This article will explain the differences between 3D printing and injection molding from five aspects: principle, processing quality, cost, production mode, and application field.

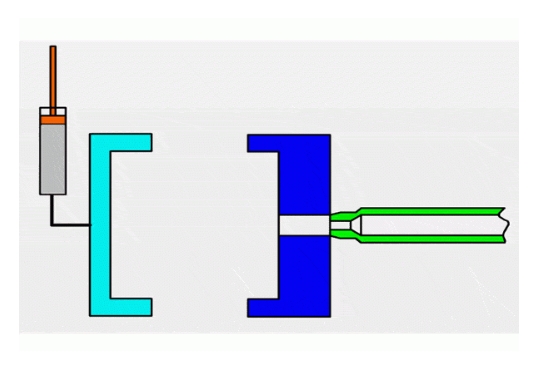

1. Comparison between 3D printing technology and injection molding principle:3D printing technology is a technology of the last century and a market of this century. 3D printing technology is a technology based on rapid prototyping technology, based on digital model files, using powdered metal, plastic and other bondable materials to construct objects by printing layer by layer. Injection molding technology is based on a method of stirring completely molten plastic materials through a screw at a certain temperature, injecting them into the mold cavity with high pressure, and obtaining molded products after cooling and solidification.

2. Comparison between 3D printing technology and injection molding production mode

Injection molding technology requires the selection of injection molds, and it can produce standardized products at low cost and on a large scale. Therefore, it is better to use injection molding technology for traditional mass production. 3D printing technology does not require traditional tools, fixtures, machine tools, etc. It relies on computer digital technology to quickly and directly make physical models of the required three-dimensional models. Therefore, 3D printing technology is more suitable for personalized and diversified product manufacturing.

3. Comparison of production costs between 3D printing technology and injection molding technology

We all know that injection molding technology uses raw materials that are easy to obtain, can be mass-produced in a standardized manner, and can reduce the cost of a single piece. However, the 3D printing materials required by 3D printing technology are relatively rare and expensive. But there is still great potential. The real savings of 3D printing technology lies in the modification of the prototype, which only requires a CAD model and does not incur any cost.

4. Comparison of production quality between 3D printing technology and injection molding:

Using a high-end 3D printer, you will know that the printed parts do not have the same physical properties, while injection molding technology not only produces parts with better physical properties than 3D printing technology, but also produces parts with better surface finish and better durability, which 3D printing technology does not have

5. Comparison of 3D printing technology and injection molding application fields:

Currently in the market, injection molding technology can realize mass production of a certain object, and is more suitable for mass processing of a certain component for standardized production, such as the production of toys, aviation, aerospace, electronics, machinery and other fields. 3D printing is a new technology that can be made into a model through digital computer technology. 3D printing materials can be made into the required model, which can effectively shorten the processing time and is widely used in children's education makers, architectural design and even the medical industry to benefit mankind.