February 17, 2025 — The CNC (Computer Numerical Control) industry continues to experience rapid growth and innovation, driven by advancements in automation, precision technology, and smart manufacturing. As companies across various sectors increasingly embrace automation to boost productivity, CNC technology plays a pivotal role in shaping the future of manufacturing

Growth in Demand for High-Precision CNC Machines

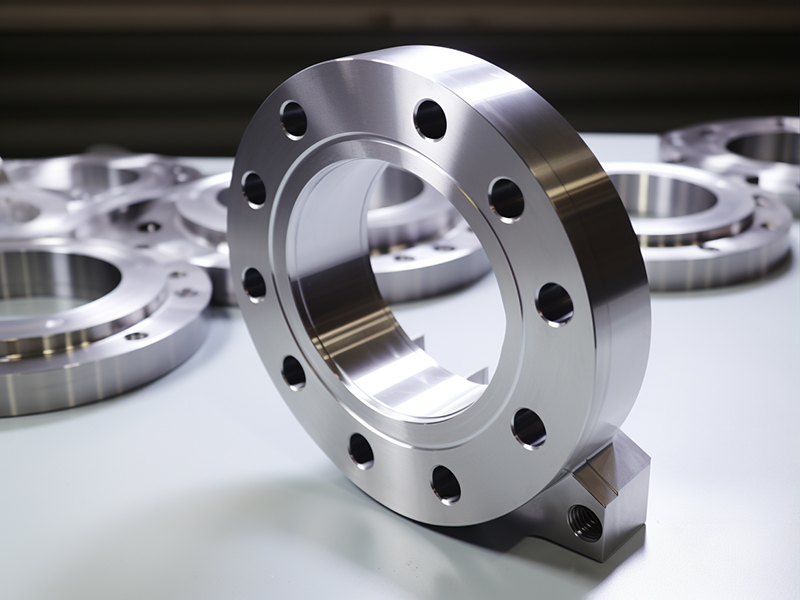

In 2025, the demand for high-precision CNC machines is stronger than ever. Industries such as aerospace, automotive, medical devices, and electronics are heavily investing in CNC technology to meet the growing need for precision parts. According to recent market reports, the global CNC machine market is expected to grow at a compound annual growth rate (CAGR) of 8.4% between 2025 and 2030, driven by the need for more efficient and cost-effective manufacturing processes.

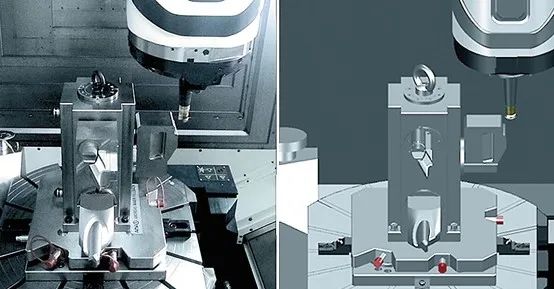

Manufacturers are embracing the latest CNC innovations, which allow for faster production cycles, reduced waste, and the ability to handle complex, custom designs with unparalleled accuracy. These advancements are enhancing the capabilities of traditional CNC machines and bringing new possibilities to industries that rely on intricate manufacturing processes.

The Rise of Smart Manufacturing

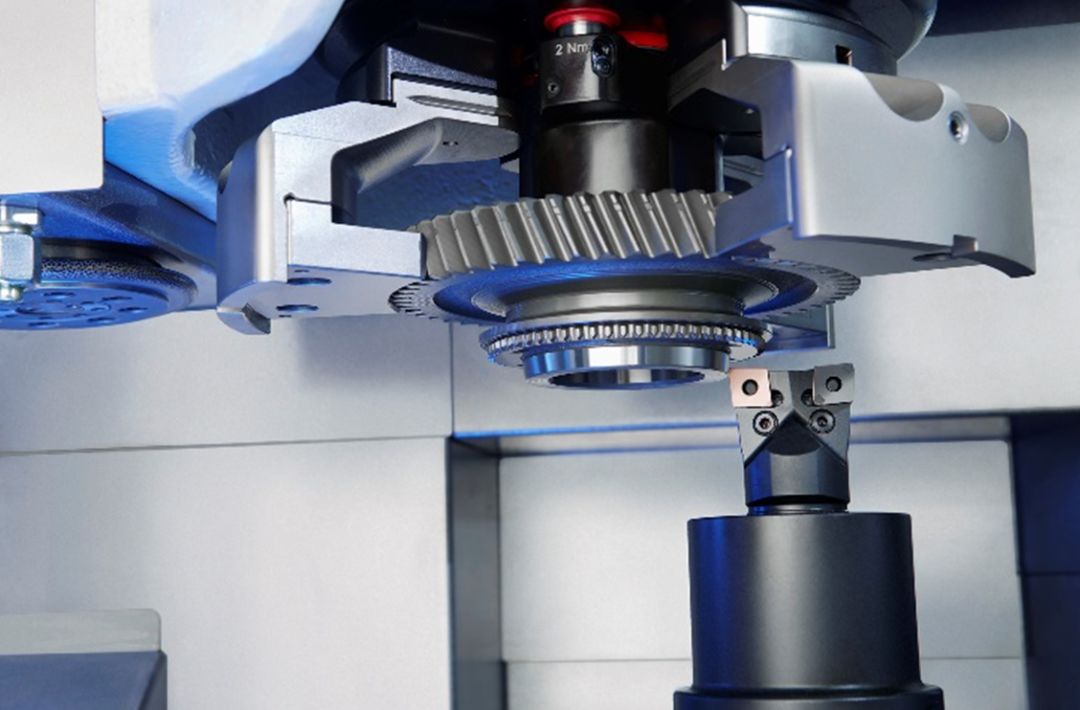

The integration of the Internet of Things (IoT), artificial intelligence (AI), and machine learning is transforming CNC operations. Smart CNC machines equipped with sensors and real-time data analytics allow manufacturers to monitor and optimize production in real-time. This "smart manufacturing" approach is not only reducing downtime but also improving overall machine efficiency and product quality.

One of the key trends in this area is predictive maintenance, where CNC machines can predict potential failures before they happen, minimizing costly downtime and enhancing productivity. As a result, businesses are focusing on maintaining an intelligent, connected infrastructure that supports continuous improvement in their manufacturing processes.

Automation and Sustainability in the CNC Sector

Automation continues to be a key driver of growth in the CNC sector. CNC machines are becoming increasingly automated, allowing manufacturers to achieve faster and more accurate production without the need for constant human intervention. In addition, automation helps optimize labor costs and makes it possible to operate CNC systems with fewer skilled workers, which is particularly beneficial in regions facing labor shortages.

Sustainability is also a growing concern for the CNC industry, with increasing pressure to reduce energy consumption and minimize waste. Manufacturers are turning to energy-efficient CNC machines and materials to meet sustainability goals. By optimizing energy use and cutting down on unnecessary production waste, these innovations are contributing to greener, more environmentally conscious manufacturing processes.

The Road Ahead for CNC

Looking to the future, CNC technology is poised to become even more integral to manufacturing processes across the globe. As industries continue to push for faster, more precise, and cost-effective solutions, the adoption of advanced CNC systems is expected to rise, providing manufacturers with the tools they need to remain competitive in a rapidly evolving market.

As 2025 unfolds, the CNC industry remains at the forefront of technological advancements, and its potential to revolutionize global manufacturing is clearer than ever..