The Integrex i-800V/8S series products are high-performance turning and milling composite machining centers launched by Mazak Corporation. The following will introduce it from aspects such as processing capabilities, performance characteristics, technical advantages, and application fields:

Processing Capabilities

Size Range: The maximum machining diameter can reach 1700mm, and the maximum machining length is 1665mm, enabling the processing of medium-sized and large complex components.

Turning Capability: The chuck size of the turning spindle is 1000mm, with a maximum speed of 500rpm and a maximum torque (continuous rating) of 3120N?m, providing powerful turning power and being suitable for processing various rotational parts.

Milling Capability: The milling spindle has multiple speed specifications available. The standard speed is 10,000rpm, and high-speed 15,000rpm or high-torque 5000rpm specifications can also be selected to meet the processing requirements of different materials and processes. The B-axis travel is 150°, and the standard tool magazine capacity is 43 tools, enabling continuous multi-process milling.

Performance Characteristics

High-precision Machining: This series of machine tools adopts advanced machine tool structure design and manufacturing processes, such as high-rigidity machine bodies, high-precision guide rails and lead screws, etc., ensuring the precision retention under high-speed cutting and heavy cutting conditions. At the same time, it is equipped with a high-precision measurement system and feedback device to achieve precise control of the machining process, and can reach a machining precision of the micrometer level or even higher.

Five-axis Simultaneous Machining: It has full five-axis machining capabilities. The positioning accuracy of the B-axis and C-axis can reach 0.0001°, enabling the machining of complex curved surfaces and polyhedral parts, reducing the number of clamping times and improving machining accuracy and production efficiency.

Efficient Automation: It is equipped with a dual pallet changer, which can realize the rapid loading and unloading of workpieces and reduce non-machining time. Meanwhile, the PALLETECH system is easy to integrate and is suitable for automated manufacturing production lines. It can cooperate with robots, automated loading and unloading devices, etc. to achieve unmanned machining.

Application Fields

Automotive Manufacturing Field

It is suitable for machining key parts of automotive engines such as cylinder blocks, cylinder heads, crankshafts, and transmission cases, improving the machining accuracy and production efficiency of automotive parts.

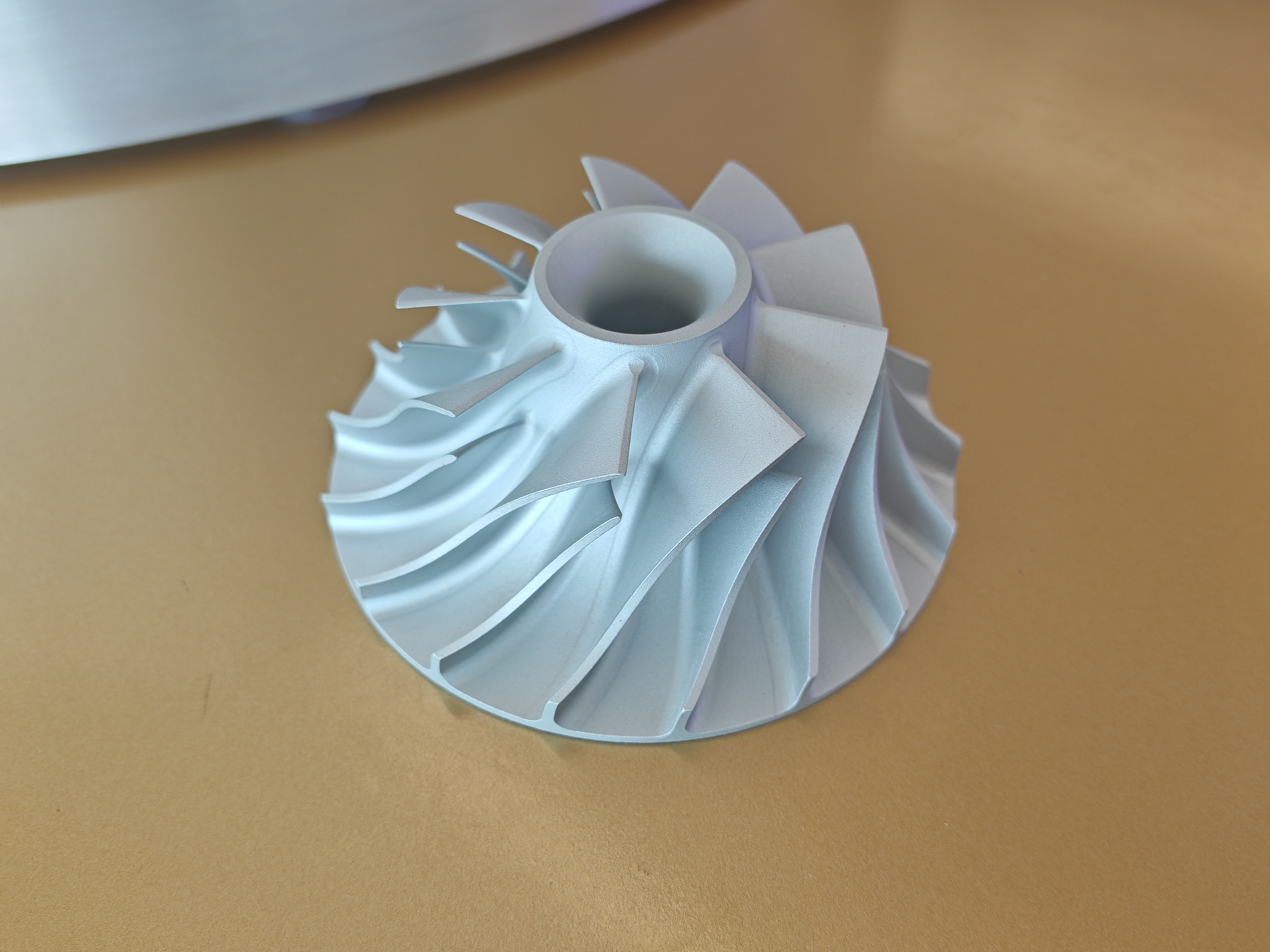

Energy Field

In the energy field, it can be used to machine parts in oil and gas extraction equipment, such as impellers, shaft parts, etc., as well as turbine blades and generator shafts in power generation equipment.

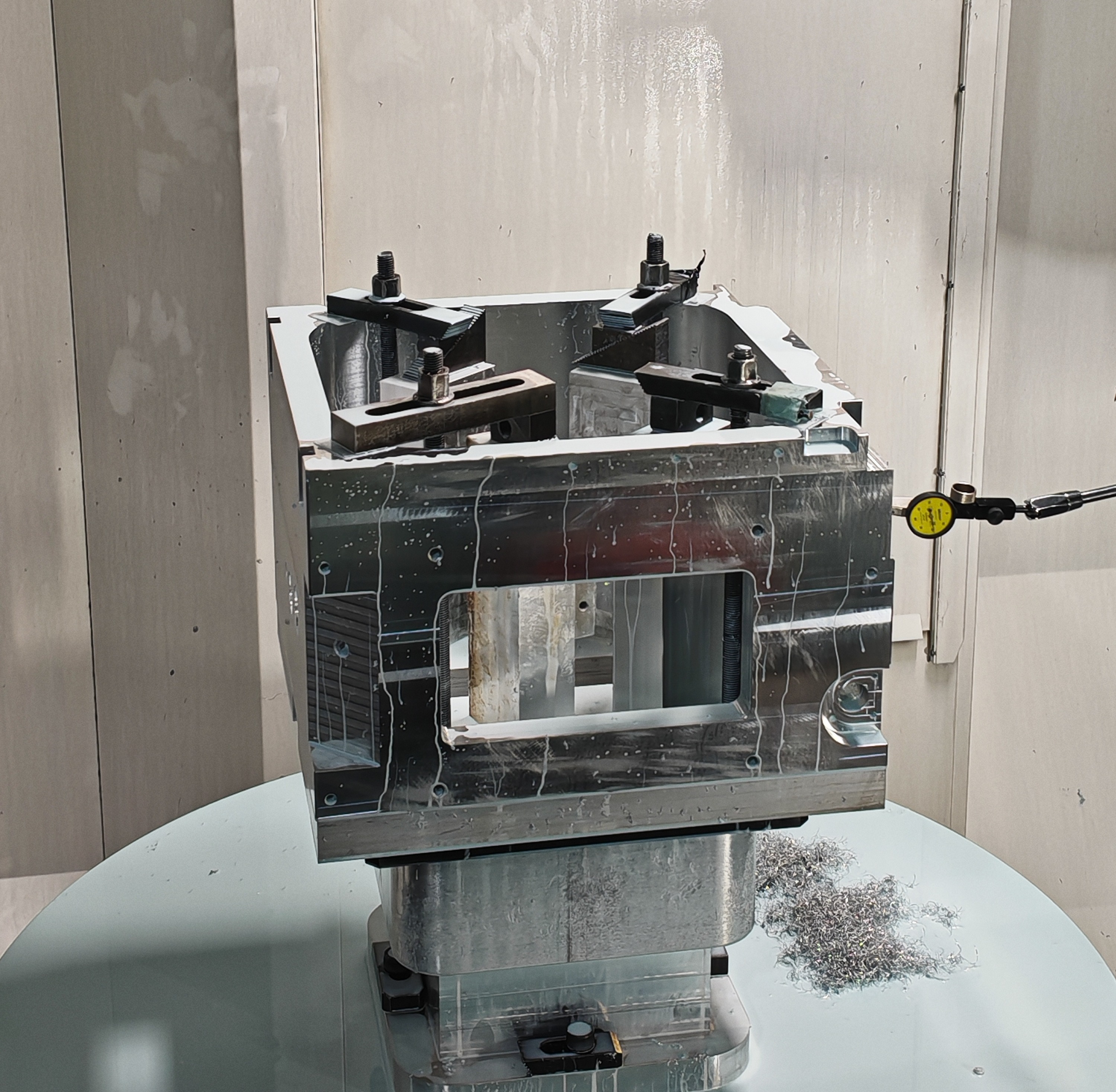

Mold Manufacturing Field:

It can machine various complex mold cavities and cores, such as injection molds, die-casting molds, stamping molds, etc., ensuring the accuracy and surface quality of the molds and shortening the mold manufacturing cycle.

Technical Advantages

MAZATROL Smooth X CNC System

It adopts the advanced MAZATROL Smooth X numerical control system, which is simple and convenient to operate and has a conversational programming function, which can greatly shorten the programming time and improve programming efficiency. At the same time, this system also has powerful graphic simulation and emulation functions, which can verify the program before machining and avoid machining errors.

Compact Milling Spindle Design

The compact inclined milling spindle design reduces workpiece interference and expands the machining range, being able to better adapt to the machining of complex-shaped parts.

Advanced Tool Management System

It has a large tool storage capacity. You can choose a standard tool magazine with 43 tools, or you can select tool magazines with 80, 120, or 160 tools according to your needs. You can even choose a large-capacity tool storage system such as Tool Hive with 180, 240, or 348 tools. In addition, the tool change speed is fast, which can improve machining efficiency.

-