Five-axis machining is a sophisticated and advanced form of CNC machining. Here's an in - depth explanation

Axes in machining

In machining, axes refer to the directions in which a cutting tool or the work piece can move. In traditional three - axis machining, the three axes are typically labeled as the X, Y, and Z axes, which move linearly. These axes allow the tool to move back - and - forth, left - and - right, and up - and - down, respectively. This setup is sufficient for many basic machining tasks, such as milling flat surfaces, drilling holes, and creating simple 3D shapes.

Five - axis machining adds two additional axes to the three - axis system. These additional axes are usually rotational axes. Commonly, they are the A - axis (rotation around the X - axis) and the B - axis (rotation around the Y - axis), or sometimes the C - axis (rotation around the Z - axis) is used in combination with one of the other rotational axes.

Working principle

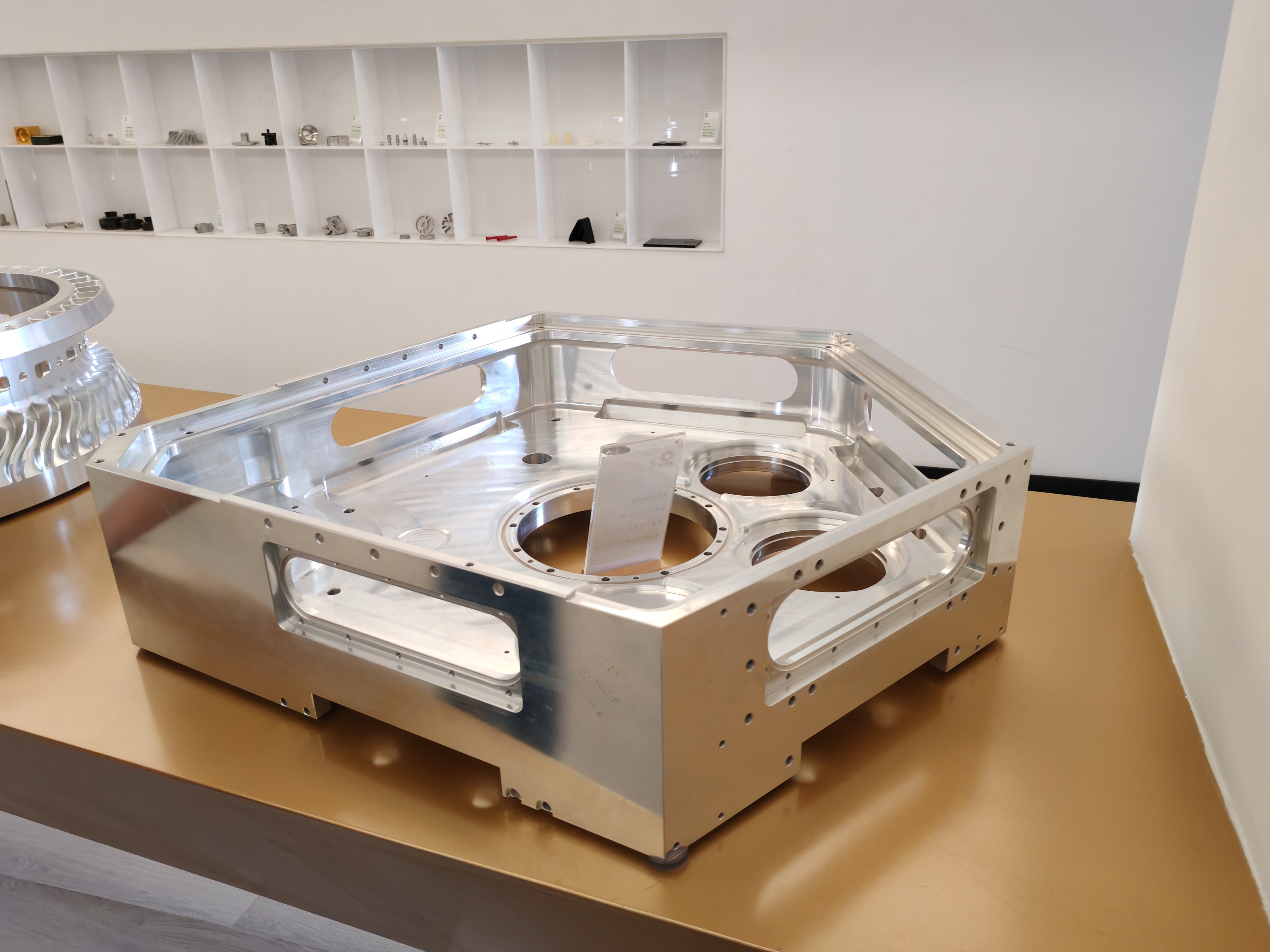

Complex surface access: The inclusion of rotational axes enables the cutting tool to approach the workpiece from a vast number of angles. This is crucial for machining complex geometries that are difficult or impossible to produce with only three axes. For example, in the aerospace industry, parts like turbine blades have intricate, curved surfaces. With five - axis machining, the tool can follow the contours of the blade precisely, maintaining a constant cutting angle and depth throughout the machining process.

Single - setup machining: Five - axis machines can often complete a part in a single setup. Since the tool can reach multiple surfaces of the workpiece without the need to re - clamp or re - position the part, it reduces the number of setups required. This not only saves time but also improves the accuracy of the final product, as each re - clamping operation in a multi - setup process can introduce small errors.

Advantages

Higher precision: By continuously adjusting the orientation of the tool relative to the workpiece, five - axis machining can achieve extremely high levels of precision. It can minimize tool - path deviations and produce parts with tight tolerances.

Better surface finish: The ability to keep the cutting tool in an optimal orientation at all times during machining results in a superior surface finish. This is especially important for parts that require smooth surfaces, such as molds for plastic injection molding or components in the medical device industry.

Increased productivity: Although five - axis machines are generally more expensive and require more advanced programming, the reduction in setup times and the ability to machine complex parts more efficiently can lead to overall increased productivity in the long run.

Applications

Aerospace: Used for manufacturing components such as engine components, wing structures, and landing gear parts. The complex shapes and high - strength materials used in aerospace require the capabilities of five - axis machining to ensure both performance and durability.

Automotive: Employed in the production of engine blocks, transmission components, and custom - designed parts. Five - axis machining helps in creating lightweight yet strong components, which is essential for improving fuel efficiency and vehicle performance.

Mold and die making: For producing molds for plastic, metal casting, and forging. The ability to machine complex cavity and core geometries with high precision ensures that the final molded or cast parts meet the required specifications.

Medical: In the fabrication of implants, surgical instruments, and prosthetics. The need for customized and precisely - shaped medical devices makes five - axis machining an ideal choice for manufacturing these components.