At Craft we harness the capabilities of Wire Electrical Discharge Machining (EDM) to produce precision-engineered components for our clients. Wire EDM is a specialized machining technique that uses electrical discharges to create intricate shapes and details in metals. By generating a controlled electrical discharge between two electrodes submerged in dielectric fluid, we can precisely cut through metal by melting and vaporizing it.

The true advantage of wire EDM lies in its ability to tackle complex contours and fine details in materials that are often difficult to machine with conventional CNC methods. This includes heat-treated steels, superalloys, and various specialty metals. With wire EDM, we achieve parts with extremely tight tolerances and intricate features like narrow slots and small holes, all with exceptional accuracy.

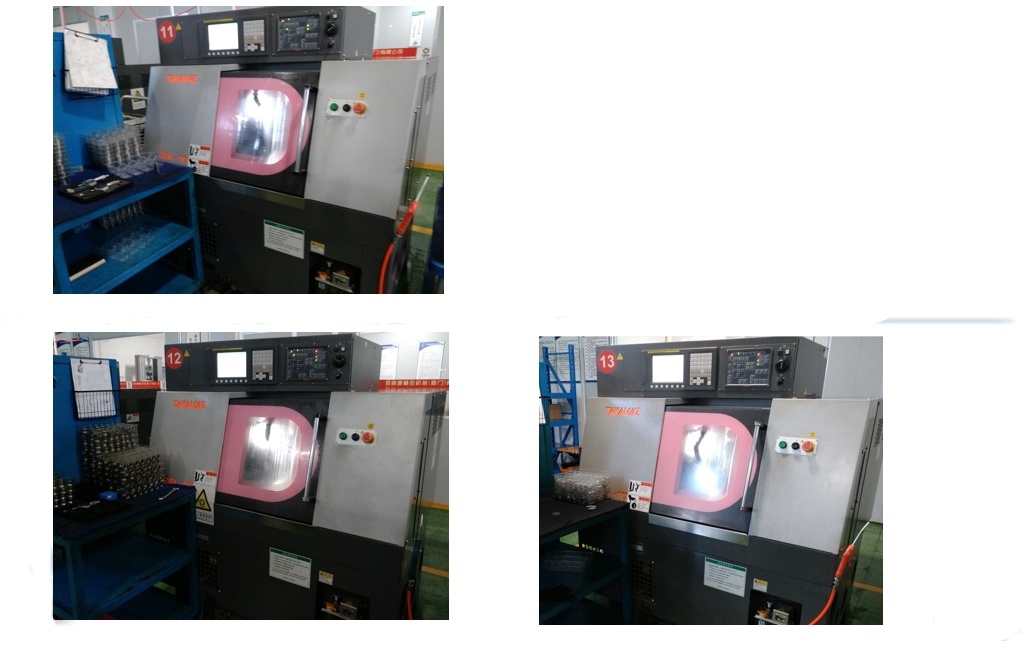

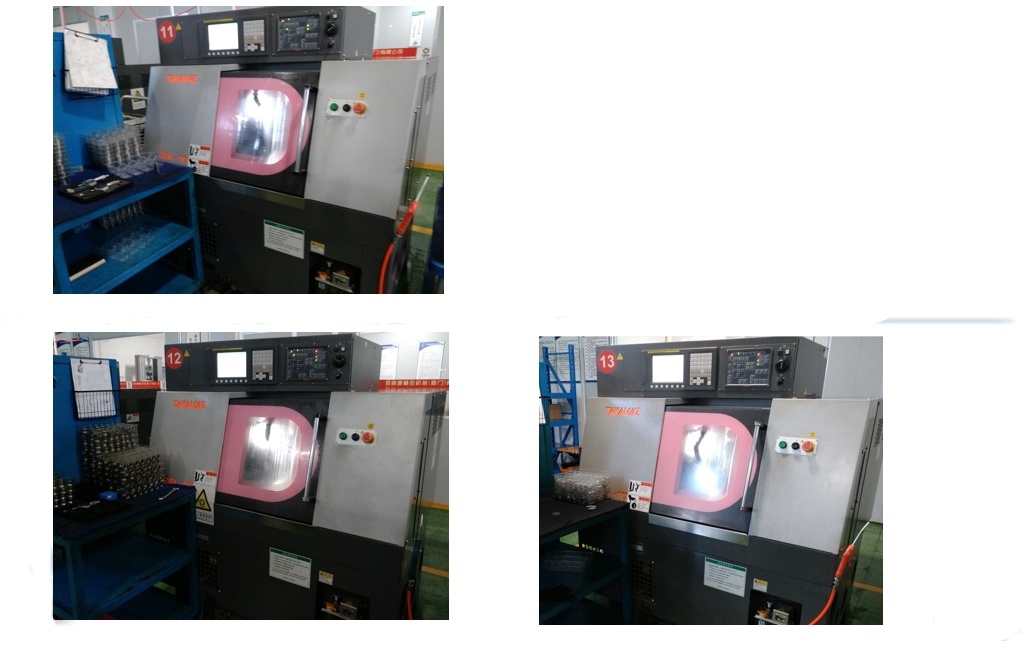

Our wire EDM services are ideal for applications demanding exacting precision. Whether it’s for aerospace components, automotive parts, or detailed molds and dies, our technology guarantees that every cut is precise and of the highest standard. Craft’s dedication to quality and precision is reinforced by our state-of-the-art wire EDM equipment and a team of skilled technicians who are experts in the field. This powerful combination positions us as a leader in wire EDM machining, ready to meet the rigorous demands of any industry.